- Home

- Method

Our Method

Fuel Filtration Process for Various Type of Tanks

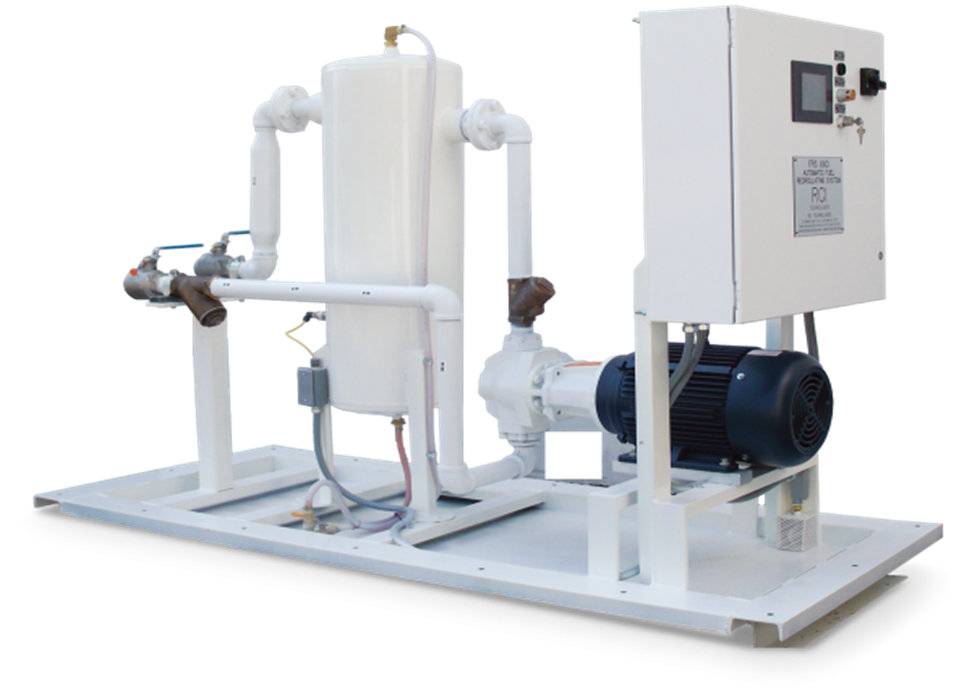

Diesel Fuel Polishing

Stand-alone, factory complete, automated, programmable,

Green Clean Certified, Fuel Filtration, Optimization and

Maintenance System shall be provided for each Diesel

Storage Tank to Optimize and Maintain the condition of

fuel stored.

Capable of eliminating microbial contamination and

removing water, sediment and particulate to comply with

ASTM D975 (Standard Specification for Diesel Fuel Oils)

Mobile Tank Cleaning

Specific Mobile Tank Cleaning Systems:

- Filter units

- Oil mist collectors

- Remove water, sludge and sediments

- Automatic paper band filters

Cleaning Process

- Check tank bottom for water with a sampler or paste on a pole.

- Fill your fuel polisher with clean fuel from top portion of the tank and observe the fuels color in the sight tube.

- Insert a suction tube to the tank bottom through a port in the tank near the submersible pump location; insert the return to tank tube in the fuel drop pipe.

- Start system and observe sight tube for a liquid color change. Water will be on the bottom, fuel on top.

- When water reaches top of sight tube, open drain valve to empty water while unit is in operation.

- Observe vacuum gauge from start of process; when gauge reading rises 15 Hg. change primary filter bag.

Filter

Filter-clogging bacterial and fungal colonies will develop at

the fuel/water interface in diesel fuel tanks. the filter

clogging microbes will be drawn into the fuel system and

stop the engine.

- A pro-active fuel tank cleaning program will prevent unexpected engine shut down.

- Remove the tank bottom water and the microorganisms will die.

- Filters will not clog.

- Tanks will not corrode from the acidic sludge.

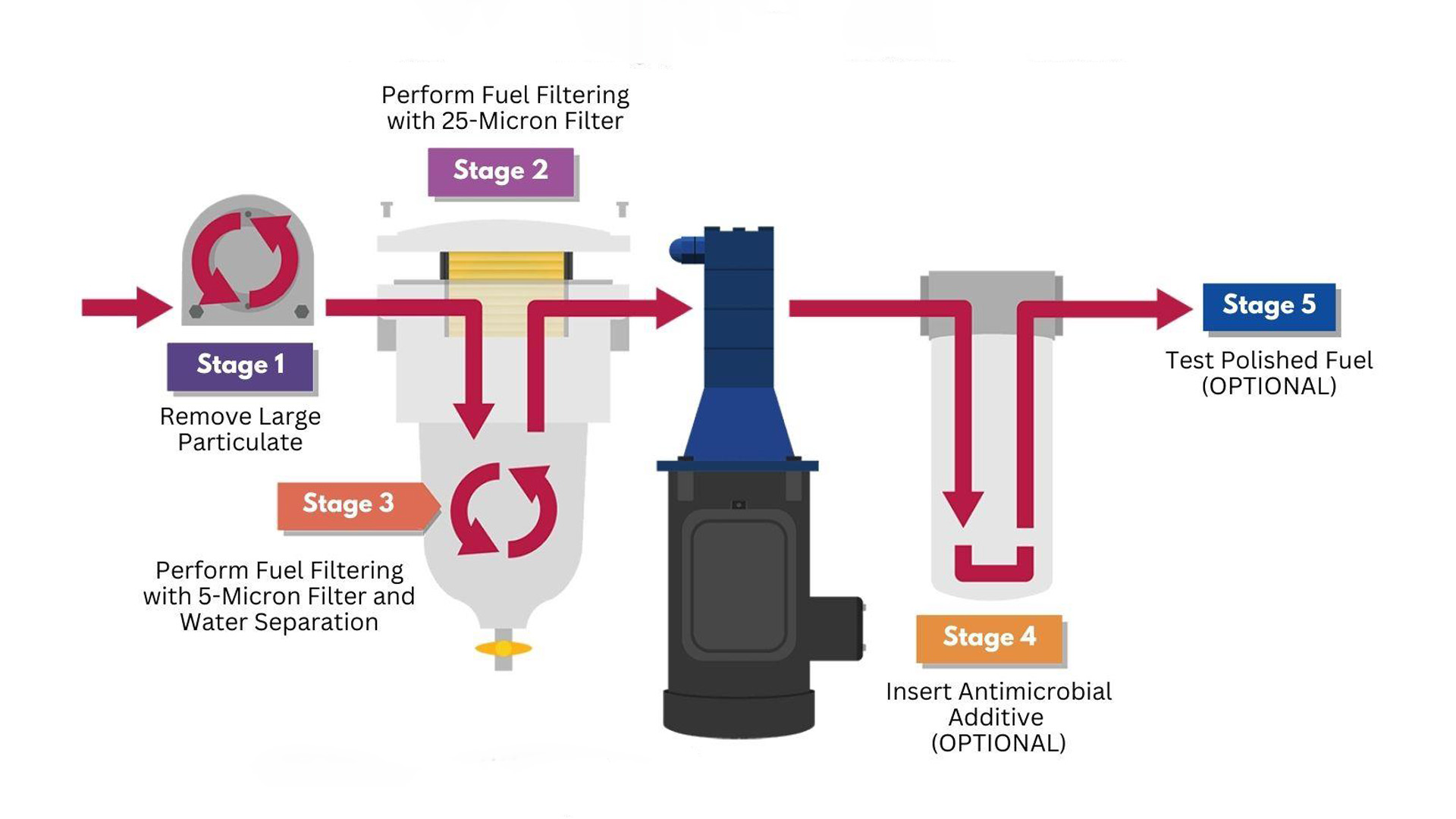

Stage of Fuel Filteration Process

These components of our standard fuel filtering process ensure effective fuel cleaning:

*Stage 1, 2 & 3 is the recommended best practice.

*Stage 4 & 5 is optional, good to be done periodically.

*Stage 4 & 5 is optional, good to be done periodically.

Importance to Remove Fuel Contamination & Sludge

Maintaining the integrity of a storage tank and the fuel it contains requires the

removal of diesel sludge.

Fuel impurities and debris that settle out over time make up sludge. Sludge separates from the fuel and usually gathers at the bottom of tanks.

ASTM Test Parameter for Diesel Fuel

(American Society for Testing and Materials)

- ASTM D 1500 - Color

- ASTM D 95 - Water by Distillation,% vol.

- ASTM D 93 - Flash Point, °C

- ASTM D 6217 - Particulate Contaminants, mg/L

- ASTM D 976 - Cetane Index

Contact Us

Get in Touch with Borneo Energy Solutions

Have questions or need expert assistance with fuel solutions? Our team is here to help! Whether it’s storage tank cleaning, desludging, or fuel polishing, we’re committed to providing reliable and sustainable services. Contact us today to discuss your needs and let us help you achieve cleaner fuel and better efficiency.